The sofa table exists primarily because no one wants to look at the back of a couch. And granted, it’s a handy place for reading lamps and perhaps some photos or display-worthy books. But the problem, for some of us at least, is that a sofa table feels a little too traditional and grown-up, sort of like joining a country club or driving an automatic. Thus the reluctance. This design is one humble attempt at having a sofa table that does its primary job of hiding the sofa without crossing any major style barriers. It even has a drawer for holding things like comics and music magazines — because you’re still cool even though you’ve learned how to decorate.

Materials

- One 36″ x 48″ (or larger) piece ¾” hardwood plywood

- Wood glue

- One 24″ x 48″ piece (or larger) ½” MDF or plywood

- 4d (1½”) finish nails

- Finish materials (see step 7)

- 7/8″ wood screws

- Four hairpin table legs with mounting screws

Tools

- Circular saw with straightedge guide

- Table saw and miter saw (if not using circular saw)

- Router with ½” or larger straight bit

- Clamps

- Square

- Jigsaw with very-fine-tooth wood blade

- Drill with pilot bits

- Hammer

- Nail set

- Sandpaper (up to 220 grit)

1. Cut the case parts.

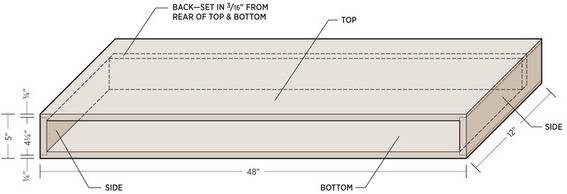

The case is the rectangular box that serves as both the tabletop surface and the drawer cabinet. Cut the case parts from ¾” plywood, using a circular saw and a straightedge guide (or a table saw and miter saw, if available). Cut the top and bottom pieces at 12″ x 48″ each, and cut the two sides at 4¼” x 12″ each; see the case plan drawing on page 98.

The case also has a ¾” plywood back panel, at approximately 3½” x 46½”. You will cut this to fit the rear opening of the case after it’s assembled.

2. Mill the rabbets.

The case is assembled with glued rabbet joints, which are stronger than butt joints and add a nice visible construction detail. Mill the rabbets with a router and a ½” or larger straight bit. Set up a straightedge guide to control the router, and mill a 3/8″-deep, ¾”-wide rabbet into the inside face of the top and bottom panels, as shown in the case plan drawing.

Test-fit the rabbets with the side pieces, and make any necessary adjustments for clean, tight joints.

Note: The width of the rabbets should match the actual thickness of the plywood stock; adjust the width as needed to fit your material.

3. Glue up the case.

Apply wood glue to the mating edges of the rabbet joints, assemble the case, and clamp it securely. Check the assembly carefully with a square to make sure all the pieces are at 90 degrees. Let the glue dry overnight.

4. Cut and install the case back.

Measure the opening at the back of the case, and cut the back panel to fit. Test-fit the panel in the case, and make any necessary adjustments.

In the table shown here, the back panel is set in from the rear edges of the case, creating a slight reveal. This adds some visual interest and gives the assembly a more finished look. It also helps hide any imperfections in the joints along the edges of the back panel. To create a reveal, mark the inside faces of the case with light pencil lines, 3/16″ in from the rear edges (or as desired). Make another set of pencil lines ¾” in from the first. Apply glue to the case parts, staying in between the two sets of lines. Slip the back panel into place until its rear face is on the reveal lines. Let the glue dry overnight.

5. Cut the drawer front.

Like the back panel, the drawer front is cut to fit the dimensions of the case, minus a little bit for clearance. Measure the front opening of the case. Cut the drawer front from ¾” plywood so that its width is 1/16″ smaller than the height of the opening and its length is 1/8″ shorter than the width of the opening.

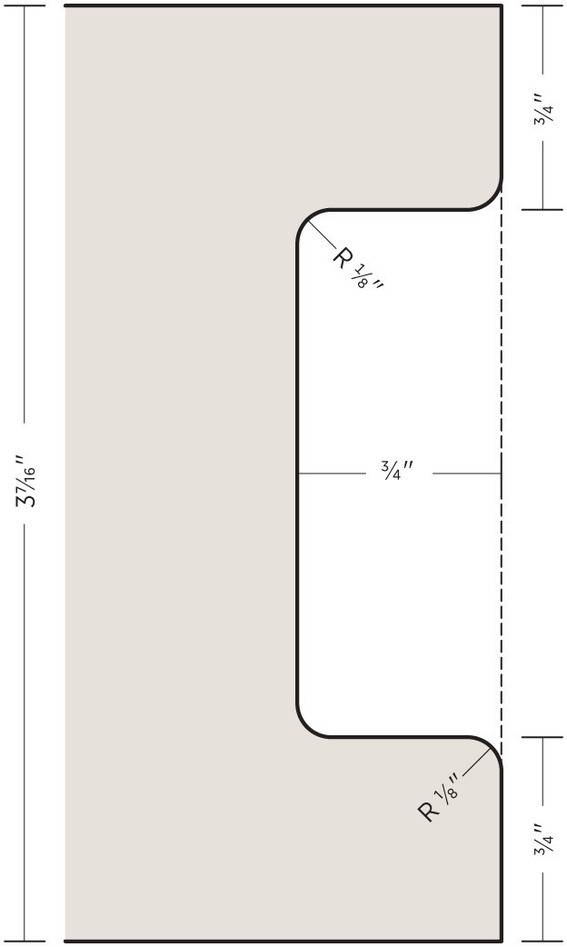

Side cutouts on each end of the drawer front serve as pulls for grasping the drawer; see the illustration at lower right. If desired, you can leave the ends square and install prefab pulls instead. To make the cutouts, draw the profiles on the ends of the drawer front, following the drawer front detail drawing. Cut out the profiles with a jigsaw and a very-fine-tooth blade.

6. Build the drawer box.

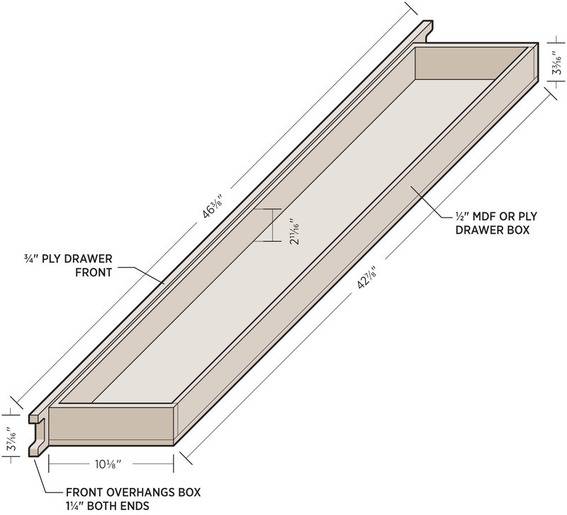

The drawer box is made with ½” MDF or plywood. Cut the box parts as follows:

- Front and back: 2 11/16″ x 42 7/8″

- Sides: 2 11/16″ x 10 1/8″

- Bottom: 10 1/8″ x 42 7/8″

Note: In use, the drawer will contact the back panel of the case when pushed in all the way. The dimensions for the sides and bottom of the drawer box shown here provide for a 3/16″ reveal at the front of the case when the drawer is pushed in. You can adjust the depth of the drawer box as desired for a different reveal or none at all.

Following the drawer plan drawing below, assemble the drawer box with glue, and clamp it securely. Drill pilot holes and fasten all the joints with 4d finish nails, setting the nail heads slightly below the wood surface with a nail set. Let the glue dry overnight.

7. Finish the case and drawer front.

Finish-sand the case and drawer front, working up to 220-grit or finer sandpaper. Finish the pieces as desired. For a decorative touch, stain the drawer front to contrast with the case, or vice versa, before adding a protective topcoat. Because the table will likely hold drinks and plates, it’s a good idea to use a moisture- and stain-resistant finish like polyurethane. Let the finish dry completely.

8. Mount the drawer front.

Clamp the drawer front to the drawer box so it overhangs the front of the box equally on both ends and sits about 1/32″ up from the box bottom. The bottom offset centers the front within the case opening. Drill two pilot holes through the drawer box and into the back of the drawer front, and tack the front on with two 7/8″ screws.

Test-fit the drawer in the case, checking for even reveals around the drawer front. Adjust the front’s position, if necessary, then secure the front to the box with four more screws driven through pilot holes.

9. Install the legs.

Position the legs on the bottom of the case so they are spaced evenly on all sides. For stability, the legs should be as close as practical to the front and rear of the case. Mark the hole locations, drill pilot holes, and mount the legs with wood screws (make sure the screws won’t protrude through the bottom of the case).

Excerpted from PlyDesign (c) Philip Schmidt. Project design by Philip Schmidt. Used with permission of Storey Publishing. Photos: (c) Lightbox Images Photography, images by Thomas Cooper