The Curbly House is moving into the ‘finishing-up’ phase, now that the walls are all closed up, taped, mudded, and sanded. Better yet, the bathroom walls and floor are ready for tile! I’ll do a post later this week about our tile-laying adventures (don’t worry, there’s no tile inspection to fail), but today I wanted point out some important safety tips. Read on to find out how I’m make cutting and setting tile an injury-free process.

I’m going to be using a wet saw to cut our tile (which happens to be a glass subway tile from ModWalls.com, although these tips apply to any type of tile). The wet saw keeps the cutting surface cool by running water over it at all times. But that means your work surface is wet, there’s backspray obscuring your vision, and your materials are slippery. Sound safe? Nope.

Here’s me practicing a few cuts on the wet saw:

Note the safety gear (I know, handsome, right?). First, I’ve got those hip-looking rubber/plastic goggles on because they protect the front and sides of my field of vision. They’re called splash/impact goggles. Don’t make the mistake of wearing normal eyeglasses, sunglasses, or even a cooler looking pair of safety glasses (like these, save them for another project). The splash goggles will make sure little bits of tile don’t go flying into your peeper-spheres from weird angles.

Note: I’m using safety gear from 3M DIY in this post. You can learn more about safe preparation at 3MDIY.com![]() , or check out their YouTube channel

, or check out their YouTube channel![]() .

.

Next: a respirator, or as I like to call it, a future-lung-transplant-preventer. Again, no one said you would look spectacular wearing this stuff. But every pass of the wet saw generates a cloud of very fine ceramic (or in our case, glass) dust that you can’t quite see but can quite definitely breathe. You don’t need anything fancy since there are no toxic fumes or anything; a simple N95 mask will work (I like the valved ones, like this).

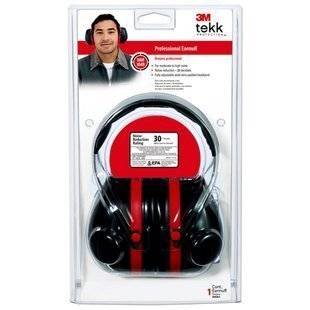

Finally, some earmuffs. Cutting tile on a wet saw is LOUD. OSHA recommends using hearing protection when exposed to prolonged noise above 85 decibels. Tile saws run between 80 and 100 (link, or check your saw’s manual). For fun, try playing with OSHA’s noise meter (TLFW – too loud for work).

I have these ones:

But you could certainly get away with using the cheaper, disposable foam plugs:

A note on gloves: wear ’em if you like, or don’t if, like me, you feel safer without them. I think the better dexterity that comes without wearing gloves actually makes me safer, and I just make sure to keep my hands well away from the blade.

(Side note: I’m using a diamond coated blade for cutting glass, and the surface is actually more like sandpaper than a saw blade, so it wouldn’t really do much damage. But I DIDN’T JUST SAY THAT, LAWYERS. So there.)

Obviously, the most important safety tip on every DIY project is to be smart, pay attention, and do things s l o w l y. Don’t rush, and you’ll be fine.

Check in again later for a full report on our tile-setting project. In case you need a reminder, here’s what the bathroom looked like before:

You can’t wait to see what it will look like after. Trust me.

This is a post in the Curbly House series! Follow along as we document every step of our complete home makeover, from gutting the walls to putting up the finishing touches. And don’t forget to let us know what you think in the comments!